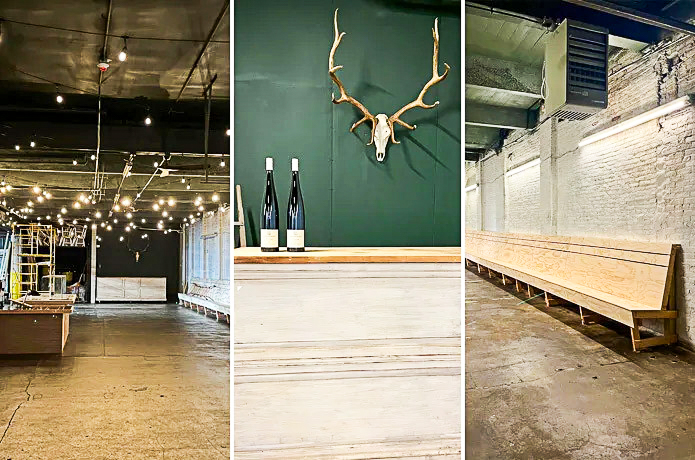

Economics professor explains national labor shortages and supply chain issues felt by the college

The renovation of the Rinek Rope factory, pictured above, may be postponed because of supply chain issues, according to VP of Finance and Administration Roger Demareski. (Photo courtesy of Lafayette Communications)

November 19, 2021

Labor shortages and disrupted supply chains have been a harsh reality since the beginning of the COVID-19 pandemic, with repercussions felt by institutions across the country. Lafayette College is no exception.

The consequences of the labor shortage are affecting daily services, especially in dining and custodial areas. According to Vice President for Finance and Administration Roger Demareski, there are 46 open positions in dining that the college is struggling to fill.

“We are not immune to the labor shortage. Even in administrative positions or other staff positions, you’re just not seeing the same volume of applicants,” Demareski said. “We have some positions that have zero applicants.”

The nation is facing both a labor shortage and high unemployment concurrently. This may lead some to question why the unemployed do not fulfill those open jobs. However, according to Professor of Economics Rexford Ahene, the matter is much more complex.

“Basically, when Covid started, we locked down the economy, and the production came to a halt. There were no purchases going on other than essential services,” Ahene said.

In order to survive, many companies had to lay off workers, sell assets and put their investments on hold. This led many to retire early, according to Ahene.

“A lot of low-skilled workers and small scale enterprises received unemployment compensation as well as stimulus benefit checks that continued for almost a whole year,” Ahene said.

The second reason for the shortage is that during the pandemic there was a shift in the quantity of low-skilled to relatively lucrative work.

“Low-skilled workers decided to take training in IT skills and short term courses that will put them in a better position, which then caused labor shortages at minimum wage jobs,” Ahene said.

The main root of these problems goes much further back, according to Ahene. With the economy transforming from manufacturing to services and many workers lacking the necessary skill set for the digital economy, structural unemployment rose.

“A lot of those people either retired or basically moved out of the labor force because there is a mismatch between the jobs that are available and the people who are looking for work,” Ahene explained.

When asked what Lafayette can do to deal with the labor shortage, Demareski offered two possible solutions: wage adjustments and promotion of the benefits of working in Lafayette.

“We’ve looked at some of the wage adjustments, and we’ve made those where we’ve needed to, but we don’t want to be in an arms race where we’re increasing expenses and get that passed along through tuition increases,” Demareski said.

Demareski added that Lafayette’s lowest paid dining workers earn $13 an hour and other rates have been increased substantially. According to Demareski, in some cases, small signing bonuses were offered. He also said that the administration is trying to come up with a benefit structure that makes people want to come work in Lafayette.

“I’m aware that we need to keep looking at what wages are around campus writ large, so both student and faculty and staff wages. And we could be excited to move on, making sure that we do some looking at our wages in the spring and try to make some adjustments,” President Nicole Hurd said.

Ahene offered another solution that he called “learn by doing.”

“Employers will have to employ people who do not meet the basic requirement and then give them on-the-job training for them to qualify to occupy jobs that currently are going vacant,” Ahene said. “You either have to pay more or you have to have incentives for training. That will attract people who need that training to develop a career skill.”

However, the labor shortage is only one side of the coin. With the shock of the pandemic and the consequent rapid economic recovery, the overall production capacity has shrunk while the aggregate demand has increased, causing supply chain disruptions.

Demareski stated that supply chain issues are felt in areas related to facilities and construction.

“The amount of time it takes to order material and its arrival have almost quadrupled. Costs are up almost five-hundred percent in some areas,” Demareski said.

Many of the college’s new construction projects are pushed back due to such shortages.

“This trend is certainly not sustainable and causes delays in College’s recent projects, such as Rinek Rope Works and renovation of Kunkel Hall,” Demareski said. “The timeline of these reconstruction projects are as follows: Parking decks will start in December and open in June. Kunkle will start in June and will be on track. Rinek might be a few months delayed.”

According to Ahene, shortages of raw materials are causing an increase in the cost of production.

“There’s too much money chasing after a small inventory of goods in the marketplace,” Ahene said. “Manufacturers want to react and respond to this demand, but they don’t have the capacity to meet the production levels necessary.”

There are also disruptions in the transportation of goods. There are no adequate means of transportation to meet the sudden upsurge of demand, many transportations workers have retired and the U.S. has been facing serious infrastructure problems.

Even though Ahene doesn’t anticipate a solution for the supply chain issues for at least another six months, he is confident that the production and delivery capacity will be adjusted and logistical constraints will be addressed.

As for what should be done by Lafayette’s administration, Ahene thinks that “in a structure like this, one has to look at local solutions.”

“Most of the goods can be produced locally, probably less efficiently, but at a scale that meets local market demand and also provides opportunity for employment and skill acquisition,” Ahene said. “It may come at slightly higher costs, but be more predictable and reliable.”