With his new organization Laf Quill Co., Remy Oktay ‘24 has turned a COVID-19 hobby into a profitable on-campus business.

Oktay first fell in love with pen turning, or the process of creating a pen out of a block of wood, when he took a year off from school during the Covid pandemic. The shared interest between Oktay and his father quickly turned into a way to give sentimental gifts to others when he began to use wood he had pruned from his property to make the pens.

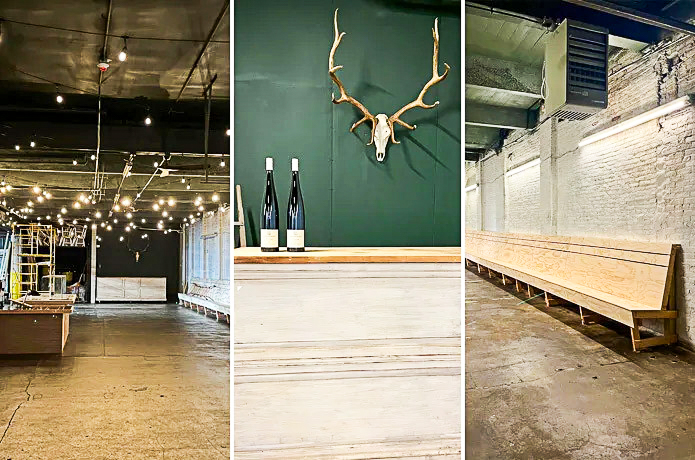

When he gifted pens to some of his professors upon returning to campus, the Lafayette version of his business was born. With the help of members of facilities operations, the development office, business administration and the art department, Oktay got wood pruned from on-campus trees, funding for several pieces of equipment and studio space to do the work.

“It’s one thing to just have an idea; it’s another thing to have funding from the art department where they say, ‘We believe in you; here’s thousands of dollars for the years that you’re here to really make things happen,’” Oktay said.

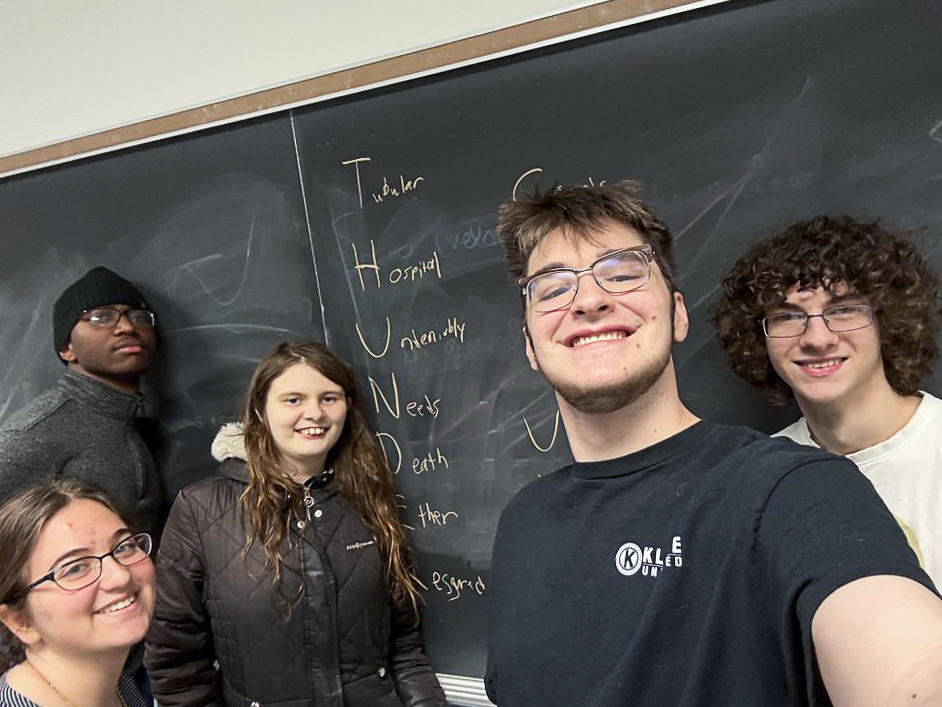

Oktay soon recruited friends with woodworking experience to join his operation. Alex Vest ‘25 decided to sign on to get back to his creative roots.

“It’s a little bit therapeutic, being able to go into this space and put on some music and drown out a little bit from the machining sounds,” Vest said. “The best part is shaping the pens. That’s where you can add a little creative flare. But generally, it’s just a really great opportunity to demonstrate some artistic ability, which is otherwise pretty lacking in my general engineering curriculum.”

Jesse Pepper ‘26, too, joined the project to have a creative space on campus.

“Before I got here, I knew that I wanted to find a way to make something related to the campus,” Pepper said. “The possibility of a woodshop sounded really cool to me.”

The team is also comprised of Owen Baute ’26 and Charles Mann ’25.

Safety is a top priority for Oktay and his team. When they work with their lathe, drill press and other equipment, all participants wear the proper masks, face coverings and gloves when applicable.

Pen turning is a multi-step process that Quill Co. members see from start to finish. It begins when they prune wood from trees on campus or acquire panels from other campus sources, like the baseboards from the Farinon construction. They then break it down into smaller, more manageable blocks of wood, which are then drilled with a hole and filled with a brass tube and sealed with glue that they mix in their workspace.

Then comes the trimming. Using their lathe, which spins the block of wood at a high speed, Oktay and his team shave the pen into any number of shapes.

“There’s really no limits to that,” Oktay said of the potential to create a variety of styles. “We’re constantly developing new crazy ideas for shapes.”

After the pens are sanded and polished, they then use a press to compress all of the pieces together.

The team currently has a waitlist of about 125 pens and is working on an order of around 100 for members of the faculty. They are focused on making the pens a meaningful object for whoever gets them. While they are testing out the ability to use laser engraving in the future to make personalized pens, they have added the special touch of a personalized note in the box in which each pen is packaged.

Their boxes, created by origami manager Anna DiFelice ‘24, are biodegradable and can be planted to become wildflowers.

In addition to the boxes, the pens are also more sustainable than the average ones on a shelf at the store. They use almost no plastic and are entirely refillable, ensuring they can be used for a long time.

Although the business is a for-profit operation, Oktay doesn’t want accessibility to be a barrier to people’s enjoyment of the sentimental objects.

“We don’t want money to be an obstacle for people to get a pen,” he said. “We’re developing a website in order to accept orders from anyone in the campus community … and we’re going to be offering a lottery-based pay-what-you-can model.”

Overall, Oktay is excited to be able to make something that connects his passions with his love for the campus community.

“I love trees, repurposing waste and making art, and this project is bringing those three together in a unique way … Making pens from trees that have been growing alongside the Lafayette community for over one hundred years is an honor,” he said.

Jim Baker P’07 • Apr 15, 2023 at 6:53 pm

How can we invest

How can we order