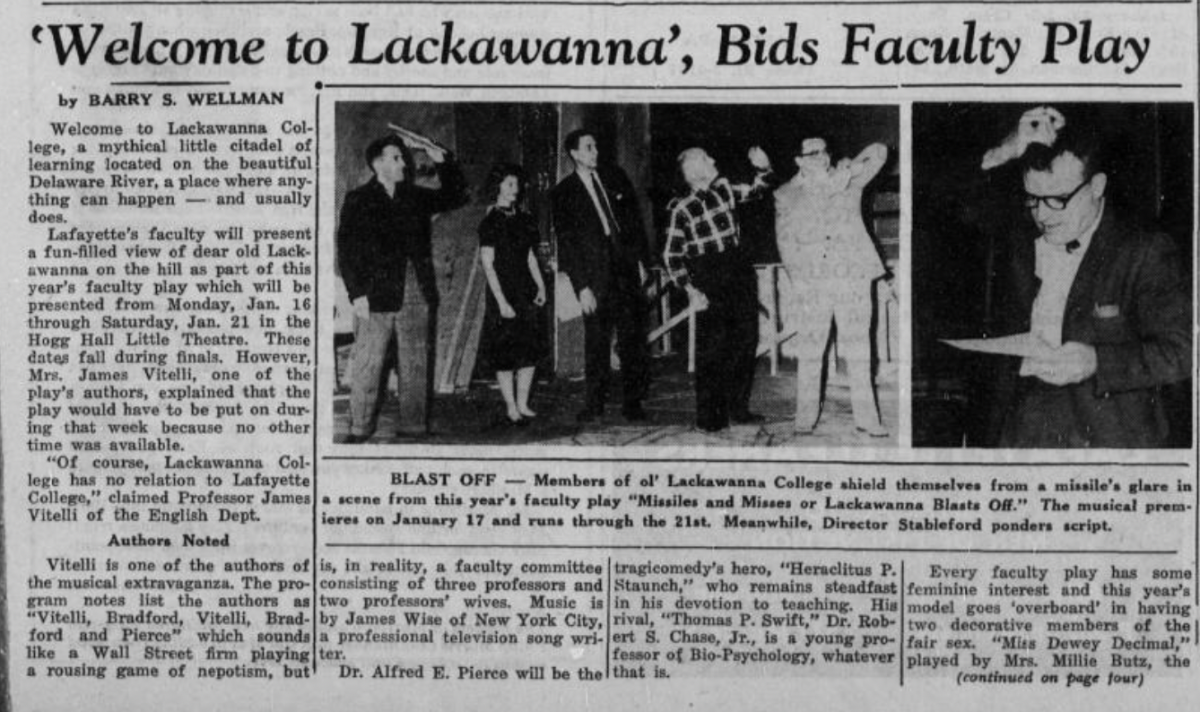

The Motorsports club has been in a race against time to finalize the design of its electric car, LM0, short for Lafayette Motorsports Zero, to compete in the Formula Hybrid competition. The competition took place from Tuesday to Thursday at the New Hampshire Motor Speedway in Loudon, New Hampshire.

Members of the four subteams — connectivity design, body panels, general mechanical and powertrain electronics — all left for New Hampshire on Sunday after a hectic weekend of final preparations.

“We were finally able to get everything on the car Saturday night and we passed all of our major electrical checks,” said senior Johnathan Cresson, lead for the connectivity design subteam. “We were able to flip on the voltage power.”

While the team was unable to get the car running in time to compete in dynamic events, it still participated in static events, like presentations in project management and design. To be eligible for dynamic competitions like testing the car, teams must pass safety inspections and have an operating car.

“Our goal is for us to learn, it’s not really for us to perform fantastically in competition,” said senior Dylan Danko, vice president of the club. “It’s great if we do, but that’s not the main goal.”

In addition to embracing the opportunity to attend the competition as a learning experience, the club enjoyed getting to be a part of the grand stage of competition.

“We are in this huge stadium, this ginormous motor raceway,” said freshman John White, a member of the powertrain electronics subteam. “Just the fact that we made it and they gave us our own garage where we unloaded our whole shop … and that we have our chance in the sun at the big leagues as a much smaller school than a lot of these other schools, it just feels great.”

Throughout the year, the club has had general body meetings once a week to give important updates on the various subteams and coordinate the week of work.

“It’s just like an extra homework assignment, except it’s fun,” Cresson said.

However fun those assignments may be, they also require a significant amount of dedication throughout the year.

“The entirety of the electrical system of the car was developed this year,” Danko said.

“We’ve had to make significant chassis modifications, and that heavily restricts what we can put where,” Cresson said. “So that goes back to my team and wiring design, like there’s tons of wires that run unnecessarily long, just because we have to work with the hunk of metal that we have.”

Beyond the electrical side, the other subteams have also had their fair share of responsibilities.

“During the year, our purpose was to make entirely new body panels for the car,” said freshman Mary Romashchenko, a member of the body panels subteam. “The chassis is old, but the body panels from previous years are not up to standard, so we had to make new ones.”

The general mechanical subteam has spent the year tending to the suspension, brakes, impact attenuator and other technical components. The powertrain electronics subteam has been responsible for testing each component of the car one-by-one and ensuring that everything is effective.

Much as the entire year has been a learning experience for the club, attending Formula Hybrid provided yet another opportunity to grow.

“Just coming up here and working all together in the shop, trying to help each other out as much as possible,” Romashchenko said. “It really, more than any time before, feels like we’re united on this one goal.”